Tungsten Heavy Alloy Machining

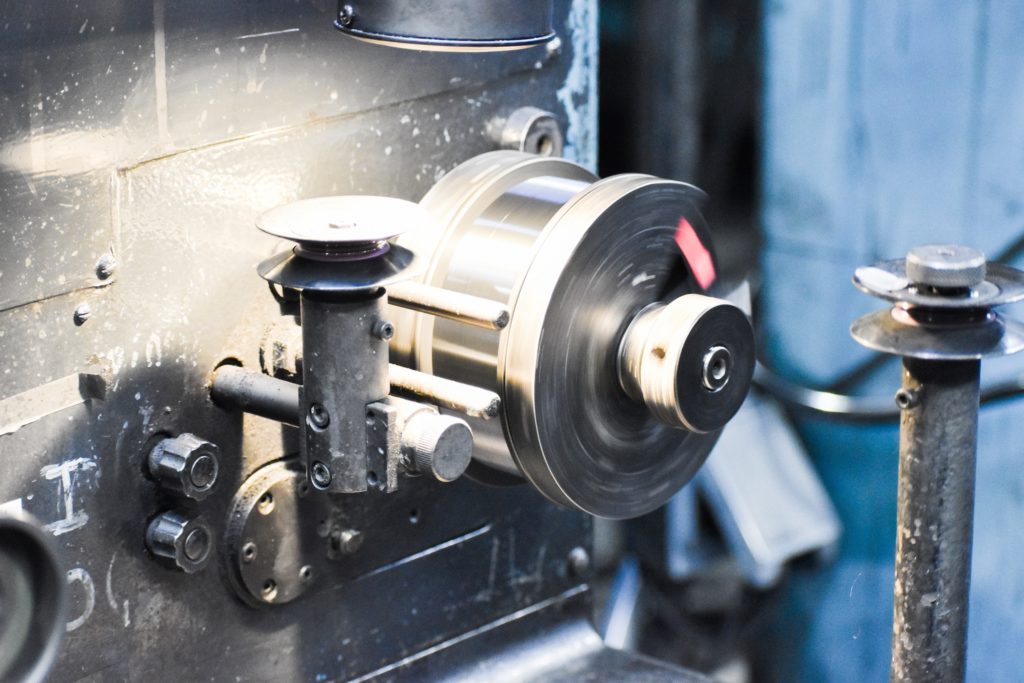

Elmet Technologies offers precision machining services for tungsten heavy alloy components. We deliver expertly crafted parts for industries that demand reliability and accuracy. From aerospace and medical to high-vacuum and electronic applications, we provide advanced machining solutions tailored to your exact specifications. Our state-of-the-art facilities handle complex designs with tolerances as tight as ±0.0005 inches. Whether you need small prototype runs or high-volume production, our team delivers quality parts and unmatched expertise to exceed your expectations.

We leverage a wide range of machining techniques, including CNC milling, EDM cutting, and waterjet cutting, to process these challenging materials with precision and consistency. As a US-based, ITAR-registered company, we adhere to strict security and compliance measures, ensuring your prints and designs are handled with care and confidentiality. Our goal is to provide you with the most efficient and reliable solutions for machining refractory metals, helping you bring your projects to life.

Custom Machining Services and Solutions

Elmet offers extensive machining services for tungsten, molybdenum, niobium, and their alloys, utilizing advanced tools and techniques to deliver exceptional results. Our capabilities include saw cutting, multi-axis CNC milling, boring, threading, tapping, and grinding. We excel in machining parts for demanding industries, offering certifications and dimensional inspection reports to ensure your parts meet both specifications and quality standards. From small prototype jobs to large production runs, we are equipped to fulfill your custom requirements.

EDM Cutting and waterjet Machining

For intricate designs and tight tolerances, Elmet employs Electrical Discharge Machining (EDM). This process allows for precise cutting and drilling in even the hardest materials, like tungsten. This method enables us to create smaller, deeper holes and complex shapes that conventional machining cannot achieve.

Our waterjet cutting services provide a fast and efficient solution for thicker materials or lower-volume production. This method works best for projects with less rigid dimensional requirements.

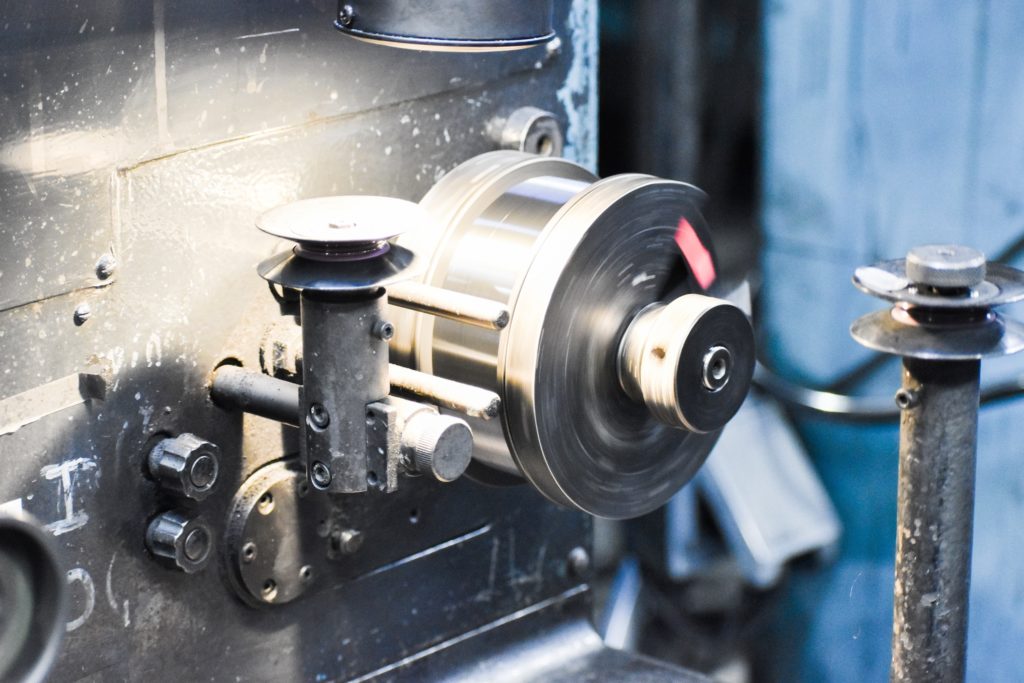

Grinding and Finishing Surface

When tight tolerances or fine surface finishes are required, Elmet utilizes precision grinding techniques. This machining service is ideal for manufacturing components from tungsten or other refractory metals, ensuring exceptional accuracy and a polished finish. Grinding is an essential part of our machine services, allowing us to meet the most demanding specifications with confidence.

Wire Forming and Component Shaping

Elmet provides wire winding and forming services for specialized applications, such as evaporation filaments, electron beam filaments, and ion beam filaments. Using custom-built, computer-controlled equipment, we ensure consistent precision and repeatability in every part we produce.

Additionally, our CNC benders and custom tooling allow us to shape wire into complex forms, meeting the unique needs of our customers. With decades of expertise, we take pride in delivering high-quality solutions tailored to demanding technical requirements.

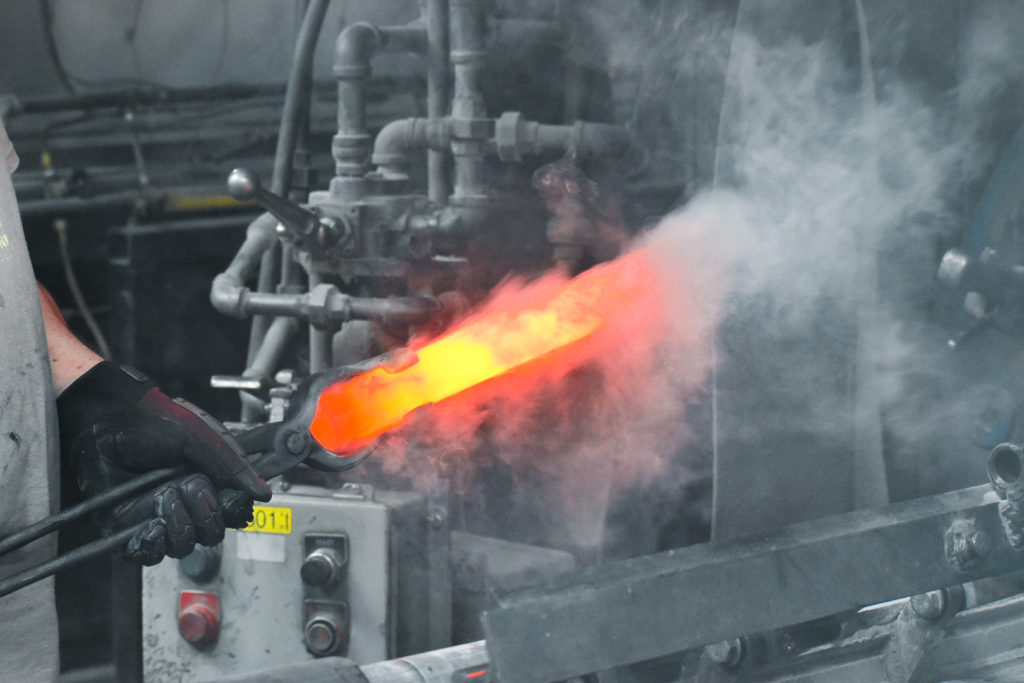

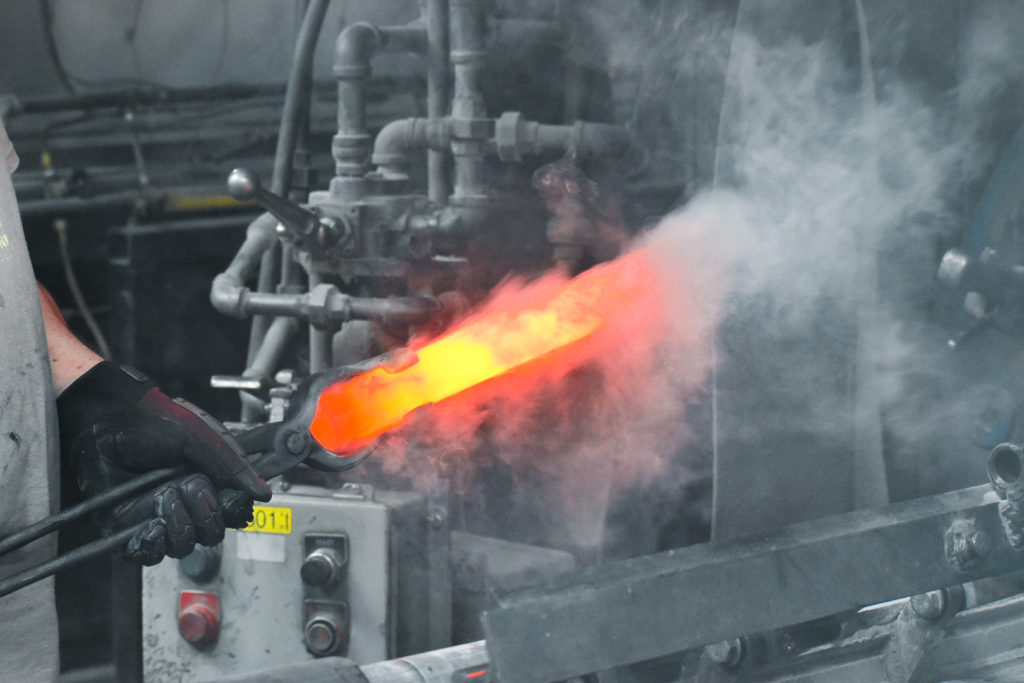

Stamping, SHEARING and Fabrication

We design our advanced machining, stamping, and forming services to process refractory metal sheets into finished components. Elmet uses CNC punches, shears, brakes, and welding equipment to fabricate custom parts with precision and efficiency. We transform tungsten and molybdenum sheets into the components you need. Our team ensures every piece meets the highest quality standards.