Tungsten Heavy Alloy Applications

Elmet Technologies specializes in developing advanced tungsten alloy materials designed for demanding applications, such as oil and gas exploration, balance weights, and radiation shielding, where precision and reliability are essential. With unmatched density, lead-free composition, and exceptional machinability, these alloys deliver superior performance in radiation shielding, high-temperature resistance, and weight efficiency, ensuring optimal results even in the harshest environments.

We provide a comprehensive range of tungsten alloy solutions tailored to meet your unique requirements. From high-density sinker bars and radiation shielding components to flat-rolled materials for critical oil and gas operations, our products are engineered to meet industry-leading standards, such as AMS-T-21014 and ASTM B777. Whether you need fully finished components or semi-finished materials for further processing, Elmet Technologies is your trusted partner in delivering innovative tungsten alloys that enhance precision, safety, and sustainability.

Why High-Density Tungsten Alloys?

Tungsten alloys are ideal when maximum weight is needed in minimal space. Their durability and ability to perform in extreme environments, like high-vacuum and elevated temperatures, make them stand out. Blended with elements like copper, nickel, and iron, these alloys are over 50% heavier than lead and twice as dense as steel, offering unmatched weight efficiency.

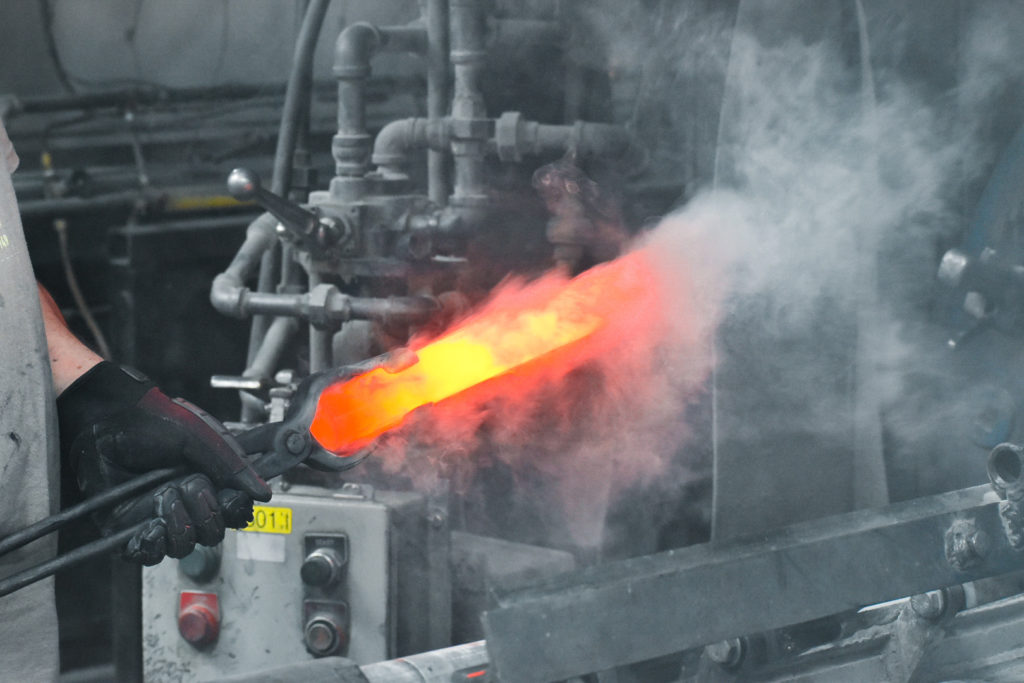

We use cost-effective powder metallurgy to produce tungsten alloys, delivering fully finished or semi-finished components tailored to your specifications. All products are lead-free and environmentally compliant, ensuring safe and sustainable solutions for your needs.

WHA Balance Weights for Aerospace Applications

Tungsten-heavy alloys are the perfect choice for balance weight applications in aerospace. With their high density and compact design, these alloys are used in critical components like helicopter rotor blades, missile guidance systems, aircraft elevators, rudders, and ailerons. They also provide excellent radiation shielding, making them ideal for both commercial and military use. Elmet Technologies offers premium, non-corrosive tungsten-heavy alloy balance weights that maximize weight in a compact form, ensuring greater flexibility and efficiency in tight spaces.

Tungsten heavy alloy Balance weight Advantages

- Provides fine balancing and vibration control in fixed and rotary-wing aircraft.

- High-density tungsten alloys with over 60% greater density than lead.

- Compact design for space-constrained applications.

- Non-corrosive and durable, ideal for long-term use.

- Custom-built solutions for precise balancing and vibration control.

- Used in flight control systems and center of gravity adjustments.

- Ideal for rotor and propeller blade balancing.

Applications in Oil and Gas Drilling

Companies widely use our tungsten alloys in sinker bar applications. These high-density weights add the necessary weight to downhole logging tool assemblies, helping tools descend through heavy borehole fluids. This ensures proper and efficient operation in challenging drilling environments.

Tungsten’s Advantages for Oil and Gas Applications

- Versatility: From balance weights and vibration absorbers to radiation shielding and heat transfer, tungsten alloys deliver unmatched functionality.

- Extreme Density: Tungsten alloys are more than 1.5 times as effective as lead in radiation absorption, making them highly efficient in space-constrained environments.

- Durability: With the highest melting point of all metals and unmatched density, tungsten alloys stand up to extreme heat and pressure.

- Environmentally Friendly: Our alloys are lead-free and comply with legal requirements to protect the environment.

Precision Engineered WHA for Critical Applications

Tungsten heavy alloy is an ideal choice for high-density applications requiring precision and durability. With decades of experience, Elmet Technologies specializes in transforming refractory metals into precise, net-shaped components that meet exacting mass and shape specifications. Trust our expertise to deliver reliable solutions tailored to your critical application needs.

Tungsten Radiation Shielding Efficiency

Tungsten alloys provide exceptional radiation shielding, delivering superior protection in high-radiation environments across medical, industrial, and scientific applications. With a density 1.5 times greater than lead, tungsten alloys effectively block X-rays and gamma radiation, ensuring safety and precision in various fields.

Key applications include:

- Scientific research (beam collimators and shields in the Large Hadron Collider).

- Medical components (X-ray tubes, anti-scatter grids, multi-leaf collimators, brachytherapy tools, syringe covers).

- Imaging and diagnostic technologies (CT scanners, PET scanners, gamma camera collimators).

- Nuclear medicine (isotope containers, shielding for radioactive materials).

Tailored Solutions to meet your needs

Elmet Technologies’ Kulite tungsten alloys are engineered to meet your specific requirements. Whether you need fully fabricated components or semi-finished products for further processing, we deliver solutions designed to perform in the most demanding applications.

Contact us today to learn more about our high-density tungsten alloys.