Tungsten Heavy Alloy

At Elmet Technologies, we provide high-performance tungsten heavy alloy, including K1700 to K1850, perfect for applications requiring maximum weight in minimal space. Twice as heavy as steel and over 50% heavier than lead, these materials are lead-free, environmentally friendly, and ideal for aerospace, defense, medical, and energy industries. Using advanced powder metallurgy, we deliver semi-finished or fully finished machined components tailored to your needs. Whether you are looking for innovative solutions or reliable materials, Elmet Technologies is your trusted partner for delivering high-quality tungsten alloys that meet the most demanding challenges.

Typical Properties of Kulite Tungsten Heavy Alloy Materials

| Alloy Description | K1700 | ET90 | K1701 | ET90NM | K1750 | ET92.5 | ET92.5NM | ET93 | K1800 | ET95 | K1801 | ET95NM | K1850 | ET97 | |

| Tungsten Content | % | 90 | 90 | 92.5 | 92.5 | 93 | 95 | 95 | 97 |

| Density | (g/cm³) | 17.0 | 17.0 | 17.5 | 17.5 | 17.7 | 18.0 | 18.0 | 18.5 |

| (lb/in³) | 0.61 | 0.61 | 0.63 | 0.63 | 0.64 | 0.65 | 0.65 | 0.67 | |

| Hardness | (Rc) | ≤ 32 | ≤ 32 | ≤ 33 | ≤ 33 | ≤ 33 | ≤ 34 | ≤ 34 | ≤ 35 |

| Ultimate Tensile Strength | (ksi) | ≥ 110 | ≥ 94 | ≥ 110 | ≥ 94 | ≥ 110 | ≥ 105 | ≥ 94 | ≥ 100 |

| (N/mm²) = Mpa | ≥ 758 | ≥ 648 | ≥ 758 | ≥ 648 | ≥ 758 | ≥ 724 | ≥ 648 | ≥ 689 | |

| Yield Strength | (ksi) | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 | ≥ 75 |

| (N/mm²) = Mpa | ≥ 517 | ≥ 517 | ≥ 517 | ≥ 517 | ≥ 517 | ≥ 517 | ≥ 517 | ≥ 517 | |

| Elongation | (%) | ≥ 5 | ≥ 2 | ≥ 5 | ≥ 2 | ≥ 5 | ≥ 3 | ≥ 1 | ≥ 2 |

| Modulus of Elasticity | (psi x 10^6) | 45 | 40 | 46 | 47 | 47 | 48 | 45 | 50 |

| (kN/mm²) | 310 | 280 | 320 | 327 | 327 | 330 | 310 | 345 | |

| Magnetic Properties | slight | none | slight | none | slight | slight | none | slight | |

| Magnetic Permeability | (µ) | > 1.05 | ≤ 1.05 | > 1.05 | ≤ 1.05 | > 1.05 | > 1.05 | ≤ 1.05 | > 1.05 |

| Thermal Expansion Coefficient | (x10^-6/K) (20ºC-500ºC) | 5.1 | 5.4 | 4.9 | 4.9 | 4.9 | 4.8 | 5.0 | 4.8 |

| Thermal Conductivity | (cgs) | 0.2 | 0.23 | 0.24 | 0.24 | 0.24 | 0.27 | 0.32 | 0.26 |

| Electrical Conductivity | (% IACS) | 11 | 14 | 12 | 12 | 12 | 15 | 16 | 16 |

| MIL-T-21014 | class | 1 | 1 | 2 | 2 | – | 3 | 3 | 4 |

| ASTM B777 | class | 1 | 1 | 2 | 2 | – | 3 | 3 | 4 |

| ASTM-T-21014 | class | 1 | 1 | 2 | 2 | – | 3 | 3 | 4 |

| AMS 7725 | Class 1 Type 2 | Class 1 Type 1 | Class 2 Type 2 | Class 2 Type 1 | – | Class 3 Type 2 | Class 3 Type 1 | Class 4 Type 2 | |

| Nominal Chemical Composiition | Ni content % Fe content % Cu content % Co content % W content % | 5.1 | 7.0 2.59 | 3.0 1.95 | = 0.1 | – 90.2 | 90.0 | 6.7 | 8.9 0.2 | 1.1 2.6 | – 0.2 | – 90.2 | 90.0 | 3.89 | 5.3 1.98 | 2.2 1.48 | – 0.1 | – 92.5 | 92.5 | 6.7 0.8 – – 92.5 | 5.6 1.4 – – 93.0 | 2.6 | 3.5 1.2 | 1.5 0.95 | – 0.21 | – 95.0 | 95.0 | 3.4 | 4.4 0.1 | 0.6 1.37 | – 0.01 | – 95.0 | 95.0 | 1.25 | 2.1 1.25 | 0.9 – | – – | – 97.5 | 97.0 |

| Other Material Names | HA170, HD 17D, HD17BB, SD170, CMW 3000, K1700, M3000, MT-17F, EA17M | HA170C, HD 17, Dens21, CMW 1000, K1701, M1000, MT-17C, EA17 | HA175, HD 17.5, SD175, K1750, MT-175, EA17.5 | – | – | HA180, HD 18D, SD180, CMW 3950, K1800, M3950, MT-18F, EA18 | HA180C, HD 18, Dens25, CMW 2000, K1801, M2000, MT-18C, EA18 | HA185, HD 18.5, SD185, CMW 3970, K1850, MT-185, EA18.5 |

Other chemical compositions are available upon request. To view the full data table, click the link below.

Tungsten WHA Materials for Demanding Applications

WHA is known for its exceptional strength, durability, and versatility, with the highest melting point of any metal and twice the density of steel. Alloyed with nickel, copper, or iron, these materials offer enhanced machinability and performance, making them ideal for demanding applications. Produced through advanced powder metallurgy, tungsten alloys provide unmatched tensile strength, ductility, and hardness, making them perfect for counterweights, radiation shielding, and precision components. Whether in semi-finished or fully machined forms, tungsten alloys are engineered to deliver reliability and precision.

High-Density Tungsten Alloy Processing

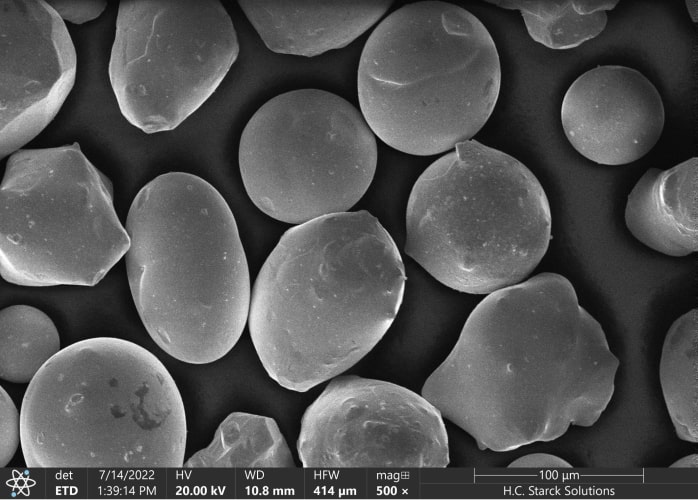

Most commercially important metals and alloys start as a casting, either in a specific shape or as an ingot. Manufacturers then work the ingot down by forging, rolling, extrusion, or a combination of these processes. In contrast, manufacturers fabricate tungsten-based high-density materials by pressing tungsten powder in a die and sintering it in a furnace to consolidate the particles.

To produce tungsten powder, workers begin with tungsten ore, found worldwide as wolframite or scheelite. They crush and concentrate the ore before chemically processing it into ammonium paratungstate (APT). They then convert the APT to tungsten oxide and reduce it to pure tungsten powder in a furnace using pure hydrogen. This tungsten powder serves as the starting material for all tungsten products.

Powder Preparation of High-Density Tungsten Heavy Alloys

Maintaining quality and uniformity requires careful grading of tungsten powder and its alloying ingredients—nickel, copper, and iron. The powders are blended using a V-blender or bar mill, with additional processing as needed for properties like increased flowability. Each lot undergoes chemical analysis and testing for characteristics like density, green strength, and flowability, with further tests on pressed and sintered specimens before production approval.

Tungsten Alloy powder pressing

A precise amount of tungsten heavy alloy powder goes into a die cavity, and the press compacts it at pressures of 10,000-30,000 psi (700-2,100 kg/cm²). The resulting “green” compact adopts the die’s shape and size, with just enough strength for further processing.

For small parts, manufacturers determine the powder amount based on its flow characteristics, while for larger pieces, they carefully weigh the powder before filling the die. Although designers typically create dies to produce parts close to the final size and shape, workers sometimes cut blanks from larger pressed pieces.

For parts like large rods that are difficult to press conventionally, workers use isostatic presses. They place a rubber mold filled with powder in a chamber and apply pressure through a liquid medium, ensuring uniform compaction.

Tungsten Alloy Sintering Process

Sintering is a thermal process that transforms compacted powder into a dense metallic structure.

- Overview: Sintering fuses individual particles into a solid mass through a diffusion-driven reaction, carefully controlled by time and temperature.

- Preparation: Pressed powder compacts are placed on trays and fed into one or more sintering furnaces.

- Pre-Sintering: Some components undergo a low-temperature pre-sintering phase to facilitate further processing.

- Furnace Operation: The compacts are moved through furnaces at a controlled pace under protective atmospheres, such as hydrogen or dissociated ammonia, to prevent oxidation.

- Final Sintering: This stage determines the final density and dimensions of the parts, typically resulting in 15-25% linear shrinkage, depending on the powder properties and pressing pressure.

- Tolerances: Shrinkage introduces dimensional variability, with tolerances limited to approximately ±1% of the nominal part size.

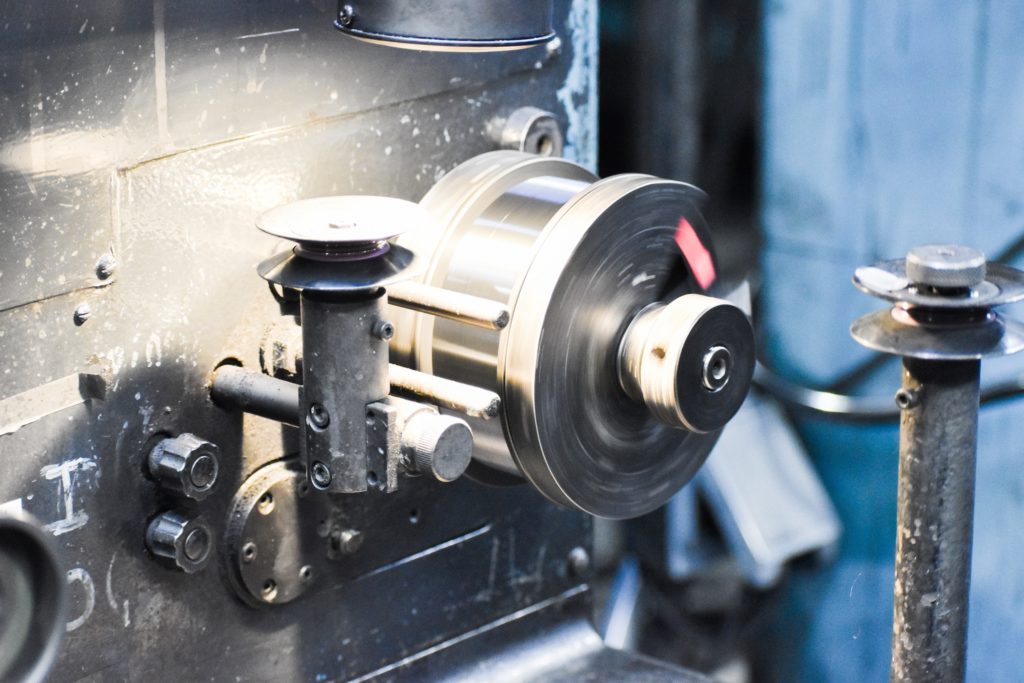

Advanced Machining Solutions for Tungsten Alloys

Elmet has developed one of the most comprehensive in-house facilities dedicated to the machining of tungsten alloys. Machining capabilities range from the most basic shapes to complex airfoil contours. We design and manufacture most of our molds, dies, and fixtures.

A wide range of CNC milling and turning centers, as well as conventional millers, lathes, and grinders, provides us with the flexibility to manufacture both short and long runs. Elmet has unmatched equipment, expertise, and experience in machining tungsten heavy alloys to meet the most demanding requirements.